2. Hluav taws xob tswj chav tsev

Tag nrho cov kab txais cov txiv neej-tshuab tswj hom sib txuas PLC thiab kov npo.Cov kev qhia tshwj xeeb, qhov ntau thiab qhov tsis zoo ntawm cov khoom tuaj yeem teeb tsa los ntawm lub vijtsam kov.Ntau cov lus qhia ua haujlwm tuaj yeem khaws cia rau ib zaug.Lub degree ntawm automation yog siab.Nws muaj lub tswb ua haujlwm thaum muaj qhov txawv txav hauv cov kab ntau lawm.Kev ua haujlwm ntawm tag nrho cov kab ntau lawm tuaj yeem raug saib xyuas los ntawm kev tswj hwm.Tom qab lub hwj chim tsis ua hauj lwm lossis kev kaw tsis zoo, kev ua haujlwm tuaj yeem txuas ntxiv mus raws li cov txheej txheem ua haujlwm yav dhau los.

| Lub npe | Hom |

| PLC | Mitsu |

| Zaus converter | Delta |

| Kov npo | Vinylon |

| Cov khoom siv hluav taws xob tsawg | Schneider |

| Servo tswj | Yaskawa |

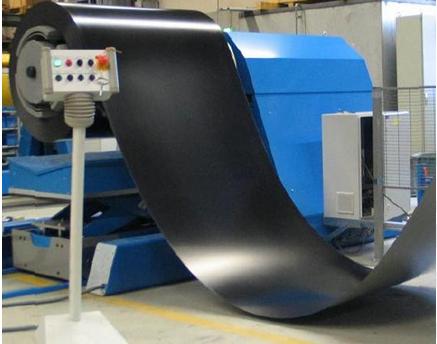

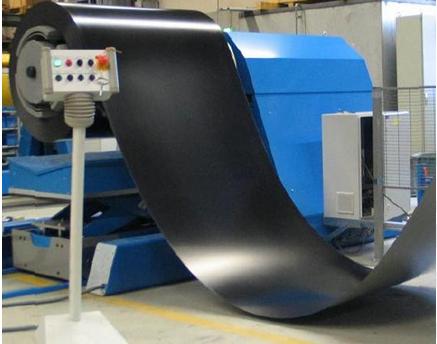

3. Cia (silo) ntaus ntawv

Cov cuab yeej khaws cia muaj ob ntu: lub arc-shaped roller thiab cov cuab yeej txhawb nqa.Muaj plaub pawg ntawm arc-shaped rollers, uas tau muab tso rau ntawm ob sab ntawm ob lub thawv ntim khoom.Lawv yog tsim los ntawm ib tug arc thav duab thiab ib txheej ntawm saj zawg zog rollers.Qhov saum npoo ntawm cov menyuam yog plated nrog nyuaj chrome.Lub tshuab hluav taws xob hloov hluav taws xob tau nruab rau hauv lub qhov dej ntawm qhov tso tawm los tswj kev nkag.Txoj haujlwm ntawm cov khoom siv yob hauv lub qhov, kom qhov ceev ntawm txhua qhov chaw ua haujlwm zoo sib xws.