Muab OEM / ODM Guardrail Plate dabtsi yog khoov yob txoj kab

Cov lus hais nrawm thiab zoo, cov kws tshaj lij qhia los pab koj xaiv cov khoom tsim nyog uas haum rau txhua yam koj xav tau, lub sijhawm luv luv, kev tswj xyuas zoo thiab cov kev pabcuam sib txawv rau kev them nqi thiab kev xa khoom rau Kev Pabcuam OEM / ODM Guardrail Plate dabtsi yog khoov Roll Forming Line, Kev lag luam pib , peb to taub ib leeg.Kev lag luam ntxiv, kev ntseeg siab tau txais muaj.Peb lub tuam txhab feem ntau ntawm koj qhov kev pabcuam txhua lub sijhawm.

Cov lus hais nrawm thiab zoo, cov kws pab tswv yim los pab koj xaiv cov khoom tsim nyog uas haum rau txhua yam koj xav tau, lub sijhawm luv luv, kev tswj xyuas zoo thiab cov kev pabcuam sib txawv rau kev them nqi thiab kev xa khoom rauTuam Tshoj Cold Roll Forming thiab laj kab Board Roll Forming, Peb kuj muab kev pabcuam OEM uas haum rau koj cov kev xav tau tshwj xeeb thiab cov kev xav tau.Nrog pab pawg muaj zog ntawm cov kws tshaj lij engineers hauv kev tsim hose thiab kev tsim kho, peb muaj txiaj ntsig txhua lub sijhawm los muab cov khoom lag luam zoo tshaj plaws thiab cov kev daws teeb meem rau peb cov neeg siv khoom.

MAIN TECHNICAL PARAMETERS

| No | Qauv | Specification |

| 1. | Khoom siv | Kub dov steel phaj |

| 2. | Yield zog ntawm raw khoom | ≤345Mpa |

| 3. | Tensile zog ntawm raw khoom: | ≤550Mpa |

| 4. | Coiling khoom sab nraud txoj kab uas hla | ≤Φ1500 hli |

| 5. | Inner diameter ntawm coil | F610 |

| 6. | Dav ntawm steel siv | ≤1550mm |

| 7. | Thickness ntawm steel siv | 8 ~ 12 hli |

| 8. | Ib yob hnyav | ≤ 20000 kg |

MAIN COMPONENTS

| No | Cov khoom npe | Specifications |

| 1 | Nws pib Decoiler | 1. Tib lub taub hau hom, ib qho kev txhawb nqa 2. Coil ID: Ф610 3. Coil OD: Ф1500mm 4. strips dav: 1700 hli 5. Max.Qhov hnyav: ≤20000 kg |

| 2 | Tshuab Leveling | Max.Ua haujlwm ceev: 15m / min Max.Strips dav: 1700 hli Max.Khoom thickness: 8mm Lub cev muaj zog: Txog 30kw |

| 3 | Shear taub qab vuam ntaus ntawv | Cov ncej yog profile + steel phaj vuam qauv, hydraulic shearing, hydraulic pressing, thiab nias platform |

| 4 | Servo pub | 1. Kev pub noj ceev tshaj plaws: 15m / min 2. Qhov siab tshaj plaws pub pub dav: ≤1700mm 3. Tso cai pub noj thickness: ≤8mm 4. Ib qho kev pub mis yuam kev: ≤ ± 1mm (qhov kev kam rau siab tsis suav nrog) 5. Servo lub cev muaj zog: ≈15Kw (raws li qhov kawg tsim) 6. Cov khoom siv ntawm cov menyuam pub mis yog: 9Cr2Mo (los yog GCr15), hardness HRC55-60 |

| Punching Xovxwm | Txais cov kua plaub-kem xovxwm hom Punching Xovxwm: 500T Qhov Loj: 15-φ25 | |

| 5 | Roll Forming Tshuab | Qauv: lub tsev tsim yog tsav los ntawm lub cev muaj zog reducer saw Tsim cov chaw nres tsheb: 24 chaw nres tsheb Kev sib sau tshuab ncej dia: φ180mm Lub cev muaj zog: 180kw Qhov siab: 2-8m / min |

| 6 | Hydraulic Txiav | Hom cutter txais blanking shearing Hniav khoom: Cr12MoV (hardness tom qab quenching HRC58 ~ 62) Parameter: txiav qhov tseeb: ± 1.5mm |

| 7 | Hluav taws xob tswj txee | Main hluav taws xob Cheebtsam: PLC: Mitsubishi Inverter: delta Kov npo: veron (Taiwan, Suav teb) Cov khoom siv hluav taws xob tsawg: schneider (Fabkis) Encoder: Omron (Nyiv) |

| 8 | Hydraulic System | Hydraulic system siv lim, kev huv ntawm cov roj kom ntseeg tau qib 6-8 |

KEV PAB CUAM

Lub culvert corrugated phaj yog corrugated hlau sheeting uas yog siv los ua cov txheej txheem ru tsev lawj lossis composite pem teb lawj.Nws yuav tau txais kev txhawb nqa los ntawm steel beams los yog joists Lub hom phiaj ntawm cov hlau lawj yog los txhawb lub insulating membrane ntawm ib lub ru tsev los yog txhawb nqa thiab kev sib raug zoo nrog cov pob zeb ua ib qho kev sib xyaw hlau hauv pem teb lawj.

APPLICATION

Lub culvert corrugated board ntau lawm kab yog ib yam khoom tshwj xeeb rau culvert corrugated board compression molding, uas yog dav siv nyob rau hauv kev tsim kho kev lag luam thiab lwm yam chaw, xws li railway choj tunnels, txoj kev loj choj tunnels thiab lwm yam.

Culvert corrugated phaj txoj kev tshuab yog ib hom tshuab siv hauv kev tsim kho culvert.Culverts yog cov qauv siv los tso cai rau cov dej ntws hauv txoj kev lossis lwm yam kev thaiv, thiab cov ntawv corrugated feem ntau yog siv los tsim cov qauv no.

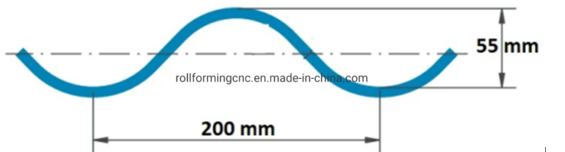

Roll forming machines yog tsim los tsim thiab khoov cov ntawv hlau rau hauv qhov xav tau thiab loj rau kev siv hauv kev tsim kho culvert.Nws feem ntau muaj cov txheej txheem ntawm cov chais uas maj mam khoov cov ntawv hlau rau hauv cov duab uas xav tau, thiab cov duab corrugated yog tsim los ntawm nias cov ntawv hlau tiv thaiv cov corrugating chais.

Cov tshuab no feem ntau loj heev thiab tuaj yeem kim, tab sis lawv yog qhov tseem ceeb rau kev tsim cov culverts kom zoo thiab meej.Ntxiv rau, lawv tuaj yeem yog qhov tsim nyog peev rau cov tuam txhab uas niaj hnub ua haujlwm ntawm cov phiaj xwm kev tsim vaj tsev.