Tshwj xeeb Shape Roll Forming Tshuab

KHOOM PLIG

Roll forming tshuab

Lub hom phiaj:Nws yog siv los nqa qhov xav tau tiav phaj zoo rau qhov kawg xav tau interface zoo los ntawm cov txheej txheem yob txoj kev.Thaum qhov txawv specifications ntawm cov khoom hloov pauv tsuas yog yuav tsum tau hloov ib feem ntawm lub tes tsho, tuaj yeem hloov cov khoom sai sai.

Qauv:Lub tsev molding txais kev ywj pheej sawv ntsug (memorial archway hom).Motor, reducer tsav, saw tsav hom

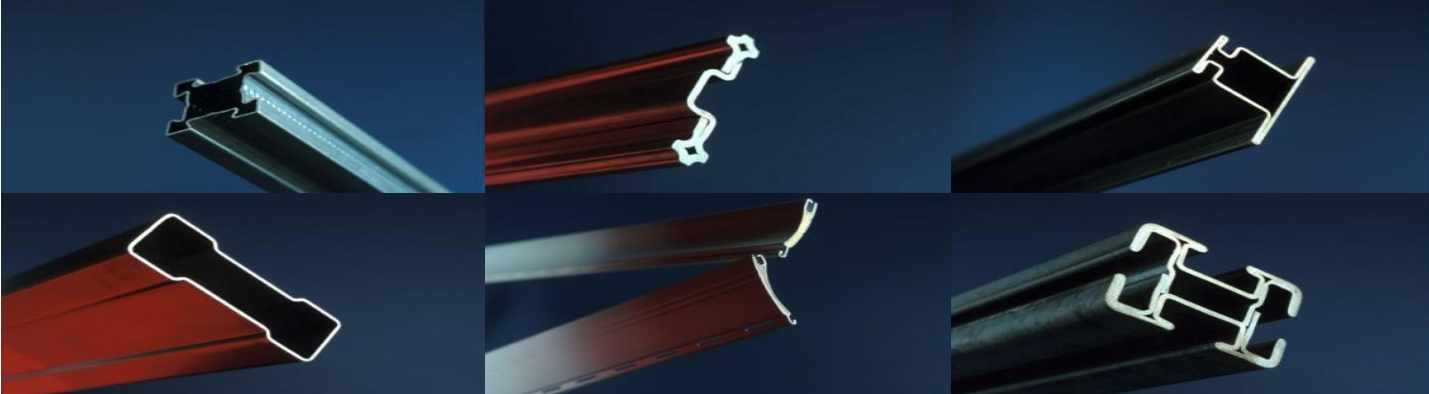

Txoj Kev Roller

Cov txheej txheem rollers tsim los ntawm kev tshaj lij software.Cov khoom siv yog ua los ntawm cov hlau zoo Cr12, thiab lub hardness tom qab quenching yog HRC58 ~ 62 (sib npaug rau American khoom D2 / D3).Cov menyuam nto yog polished tom qab ua tiav, nrog siab precision thiab ntev kev pab cuam lub neej.

Tsav ncej qis, nws yog ib qho tsim nyog yuav tsum tau siv lub tshuab synchronous rau sab sauv thiab qis.

Cov txiv ntseej sab nraud ntawm lub cim nco txog yog ob yam: sab laug (sab laug) thiab sab xis (sab sauv).

TECHNICAL PARAMETERS

| Specifications | |

| Raw Khoom | me me hlau, stainless hlau |

| Raw khoom tensile zog | <750 Mpa |

| Daim ntawv dav | ≤200 hli |

| Daim ntawvtuab | ≤1 hli |

| Tag nrho qhov loj ntawm kab | 5000 X 2000 X 1600 |

UA hauj lwm