OEM / ODM Cov Khoom Siv Hlau Hlau Lathe Glazed Pobzeb Roll Forming Tshuab

Peb txoj kev loj hlob nyob rau hauv cov khoom siv tshiab, cov txuj ci zoo heev thiab rov ua kom muaj zog thev naus laus zis ntau ntxiv rau OEM / ODM Cov Khoom Siv Hlau Hlau Lathe Glazed Pobzeb Roll Forming Tshuab, Peb tau tshawb nrhiav ua ntej los tsim kev sib raug zoo nrog koj.Nco ntsoov hu rau peb kom paub meej ntxiv.

Peb txoj kev loj hlob nyob rau hauv cov cuab yeej tshiab, cov txuj ci zoo heev thiab rov ntxiv dag zog rau kev siv tshuab rauTuam Tshoj Pobzeb Roll Forming Tshuab thiab Glazed Ua Tshuab, Los ntawm kev nruam ntej, peb yuav muab koj cov khoom muaj txiaj ntsig ntau dua thiab cov kev daws teeb meem thiab cov kev pabcuam, thiab tseem ua rau muaj txiaj ntsig rau kev tsim kho tsheb hauv tsev thiab txawv teb chaws.Cov tub lag luam hauv tsev thiab txawv teb chaws zoo siab tos txais tuaj koom nrog peb kom loj hlob ua ke.

KHOOM PLIG

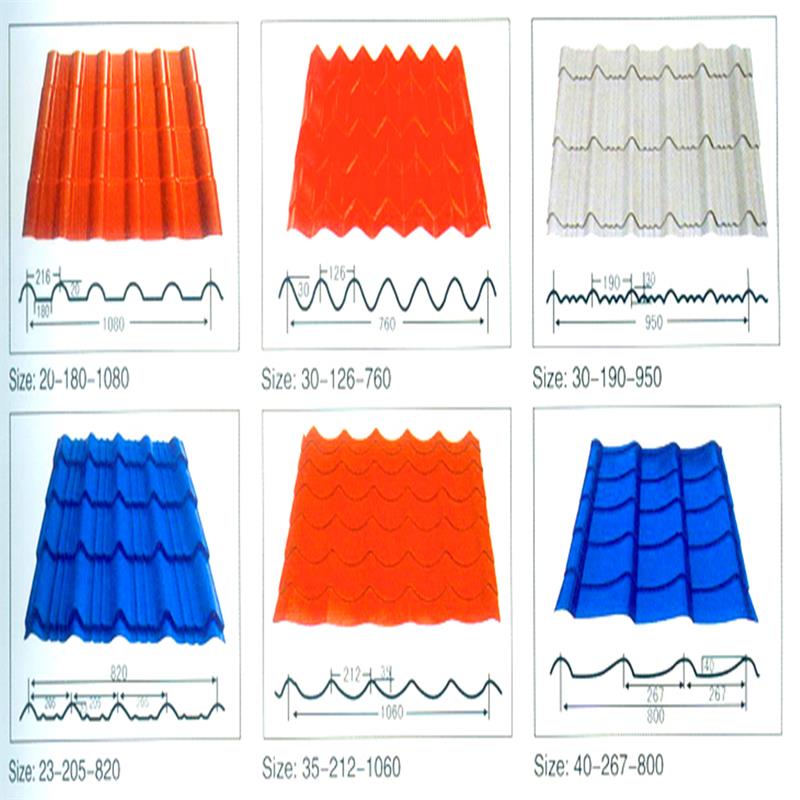

Qhov no glazed pobzeb yob txoj kev tshuab yog siv los ua cov pobzeb glazed, uas yog dav siv nyob rau hauv factories, tsev, tsev so, villas thiab lwm yam industrial thiab civil vaj tse.

MAIN PARAMETERS

Khoom siv: Galvanized ntawv

Tawm lub zog ntawm cov ntaub ntawv raw: ≤235Mpa

Tensile zog ntawm raw cov ntaub ntawv: ≤550Mpa

Sab nraud txoj kab uas hla: ≤Ф1300mm

Inner Diameter ntawm Coils: Ф508

Hlau pluaj dav: ≤1000mm

Hlau hlua Thickness: 0.2 ~ 0.4mm

Luj / Coil: ≤5000 kg

PRODUCTION PROCESS

Glazed vuas manufacturing tshuab khoom yog ua raws li cov txheej txheem hauv qab no:

Uncoiling → Looper (Storage) → Cold forming → Pressing Table & Cutting → Discharging

MAIN COMPONENTS & Specification

| No | Cov khoom npe | Specifications |

| 1 | Decoiler | Phau ntawv hom;Coils ID: Ф508mm;Coil OD: Ф1300mm;Coil Dav: 1000mm;Coil hnyav: ≤5000 kg |

| 2 | Roll Forming Tshuab | Lub tshuab tsim yog tsav los ntawm lub cev muaj zog, reducer thiab sub-reducer.Moulding tshuab memorial arch rau kev ywj pheej memorial arch qauv (tsis yog - phaj qauv), kev ua haujlwm ruaj khov, txhim khu kev qha, siab precision.Lub hauv paus yog welded steel qauv.Annealing tom qab vuam.Lub molding cov menyuam yog tsim los ntawm kev software, thiab cov khoom yog ua los ntawm zoo 45 steel thiab nyuaj chrome plating.Daim ntawv hla tebchaws: 16 kis (kwv yees rau qhov kawg tsim);Ncej txoj kab uas hla: φ70mm (raws li qhov kawg tsim);Lub cev muaj zog: 5.5kw Qhov siab tshaj plaws linear ceev: 2 ~ 5 m / min |

| 3 | Hydraulic Txiav | Cutter hom adopts tsis muaj seem txiav.Cutter khoom: Cr12MoV (hardness yog HRC58 ~ 62 tom qab quenching);Kev ntsuas qhov tseeb: ± 1.5mm |

| 7 | Hluav taws xob tswj txee | PLC: Mitsubishi;Inverter: Delta;Kov npo: Vinylon (Taiwan, Tuam Tshoj);Cov khoom siv hluav taws xob tsawg: Schneider (Fabkis);Encoder: Omron (Nyiv) |

| 8 | Hydraulic System | Hydraulic system siv lim, kev huv ntawm cov roj kom ntseeg tau qib 6-8 |

KEV PAB CUAM

Glazed pobzeb yob txoj kev tshuab; glazed vuas manufacturing tshuab; glazed pobzeb txoj kev tshuab

Peb txoj kev loj hlob nyob rau hauv cov khoom siv tshiab, cov txuj ci zoo heev thiab rov ua kom muaj zog thev naus laus zis ntau ntxiv rau OEM / ODM Cov Khoom Siv Hlau Hlau Lathe Glazed Pobzeb Roll Forming Tshuab, Peb tau tshawb nrhiav ua ntej los tsim kev sib raug zoo nrog koj.Nco ntsoov hu rau peb kom paub meej ntxiv.

OEM / ODM tus neeg muag khoomTuam Tshoj Pobzeb Roll Forming Tshuab thiab Glazed Ua Tshuab, Los ntawm kev nruam ntej, peb yuav muab koj cov khoom muaj txiaj ntsig ntau dua thiab cov kev daws teeb meem thiab cov kev pabcuam, thiab tseem ua rau muaj txiaj ntsig rau kev tsim kho tsheb hauv tsev thiab txawv teb chaws.Cov tub lag luam hauv tsev thiab txawv teb chaws zoo siab tos txais tuaj koom nrog peb kom loj hlob ua ke.