OEM Supply Roller Shutter Door Roll Forming Machinery Manufacturers Nqe

Persisting nyob rau hauv "Zoo zoo, sai xa tuaj, Aggressive nqi", peb tau tsim kev koom tes ntev nrog cov neeg yuav khoom los ntawm txhua tus neeg txawv teb chaws thiab domestically thiab tau txais tshiab thiab yav dhau los cov neeg 'cov lus siab rau OEM Supply Roller Shutter Door Roll Forming Machinery Manufacturers, Nrog rau qhov zoo ntawm kev tswj hwm kev lag luam, lub tuam txhab feem ntau tau cog lus los txhawb cov neeg siv khoom los ua tus thawj coj hauv kev lag luam hauv lawv cov kev lag luam.

Persisting nyob rau hauv "High zoo zoo, sai xa tuaj, Aggressive nqi", peb tau tsim kev koom tes ntev nrog cov neeg yuav khoom los ntawm txhua tus neeg txawv teb chaws thiab domestically thiab tau txais tshiab thiab yav dhau los cov neeg 'cov lus siab rau, Nrog kev kawm zoo, tshiab thiab nquag cov neeg ua haujlwm, peb ' tau ua lub luag haujlwm rau txhua yam ntawm kev tshawb fawb, tsim, tsim khoom, muag thiab kev faib tawm.Los ntawm kev kawm thiab tsim cov tswv yim tshiab, peb tsis yog ua raws nkaus xwb tab sis kuj yog thawj coj kev lag luam zam.Peb mloog zoo rau cov lus teb los ntawm peb cov neeg siv khoom thiab muab cov lus teb tam sim.Koj yuav tam sim xav tias peb cov kws tshaj lij thiab kev pabcuam zoo.

MAIN TECHNICAL PARAMETERS

Tso cai coil ID:ib 508

Maximum tso cai yob txoj kab uas hla:Φ1500 hli

Maximum tso cai yob dav:200 hli

Maximum yob nqa hnyav:≤ 2000 kg

Archway khoom:qw 450.

Roller ncej khoom:40Cr, quenched thiab tempered, hardness yog HRC45 ~ 50

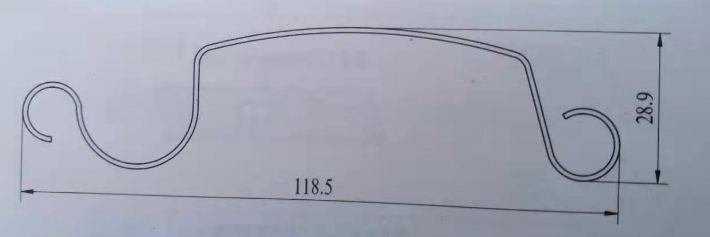

Parameters: Tsim cov ntawv hla tebchaws:14 passes (yuav mus rau qhov kawg tsim)

Ncej txoj kab uas hla ntawm txoj kev tshuab:φ50mm (raws li qhov kawg tsim)

Lub cev muaj zog:5kw DC lub cev muaj zog (Nanyang lossis Ace)

Maximum linear ceev:2 ~ 8m / min

MAIN COMPONENTS

3.1 2 tuj ib lub taub hau unpowered decoiler 1 teeb

Uncoiling: Lub tshuab yog nyob rau hauv ib lub taub hau hom.Ib qho kev txhawb nqa, manually kho cov khoom yob ntawm cov khoom siv uncoiler ncej.Qhov kev ua haujlwm yog ruaj khov thiab txhim khu kev qha.

3.2 Phau Ntawv Qhia Pub 1set

Kev qhia pub mis, tsim nyog tsim, tuaj yeem kho tau ntawm ib sab thiab txav tau ntawm sab nraud, cov ntsia hlau ntsia hlau tau hloov kho, thiab txoj haujlwm tso saib qhia qhov ntsuas.

Cov ntawv qhia ntawm ob sab ntawm lub phaj yog cov cua sov kho kom ntseeg tau qhov hardness.

3.3 Precision yob txoj kev unit 1set

Muaj ob hom txiv ntoo nyob rau sab nraud ntawm lub archway: sab laug (sab laug) thiab sab xis (sab sauv).

3.4 Hydraulic Shearing:

Nres shearing, txiav txais blanking txiav los xyuas kom meej qhov kev ncaj ncees ntawm qhov arc.

3.5 Hluav taws xob tswj qhov system:

| No | Yam khoom npe | Hom |

| 1 | PLC | Schneider |

| 2 | Inverter | Schneider |

| 3 | Cov khoom siv hluav taws xob tsawg | Schneider |

| 4 | Encoder | Schneider / Omron |

| 5 | Kov npo | Vinylon |

3.6 Hydraulic System:

Lub kaw lus hydraulic yog lub kaw lus hydraulic ceev, haum rau kev kub ceev punching, perforating yob thiab shearing txias dabtsi yog khoov cov kab ntau lawm.Lub ntsiab hydraulic Cheebtsam txais yuav Beijing Huade khoom.

Cov khoom tseem ceeb yog: roj twj, lub cev muaj zog, hydraulic valve, solenoid valve, lim thiab hydraulic tank,

Lub tshuab hydraulic txais lub lim, thiab cov roj huv huv tau lees paub tias yog qib 6-8.

KEV PAB CUAM

Roller shutter qhov rooj yob txoj kev tshuab;roller shutter qhov rooj ua tshuab;dov shutter qhov rooj tshuab.

Rolling shutter door forming tshuab yog ib yam ntawm cov tshuab siv los tsim cov qhov rooj dov.Nws yog tsim los ua yob txoj kev, nyob rau hauv uas ib tug nruam hlau sawb yog noj mus rau hauv ib tug chaw nres tsheb nyob rau hauv uas nws yog maj mam tsim nyob rau hauv lub xav profile rau ib tug dov qhov rooj.

Lub tshuab feem ntau suav nrog cov txheej txheem ntawm cov menyuam, cov lus qhia thiab cov tshuab txiav kom ua tiav cov txiaj ntsig zoo thiab zoo ib yam.Cov qhov rooj rau cov menyuam feem ntau yog siv rau kev ruaj ntseg thiab kev tswj xyuas hauv kev lag luam thiab kev lag luam ib puag ncig.Roll forming tshuab tuaj yeem tsim cov qhov rooj no hauv cov ntim siab nrog cov yam ntxwv customizable xws li loj, xim thiab cov khoom siv.Nws tuaj yeem tsim cov qhov rooj hauv ntau qhov profile, nrog rau cov qhov rooj slatted thiab perforated tsim.

Cov tshuab no feem ntau yog siv los ntawm cov tuam txhab lossis cov tuam txhab koom nrog hauv kev tsim cov qhov rooj dov.Lawv tuaj yeem ua haujlwm manually lossis txiav, nyob ntawm lub tshuab tshwj xeeb thiab nws lub peev xwm.

Ua ntej yuav nqis peev rau hauv lub qhov rooj dov txoj kev tshuab, nws yog ib qho tseem ceeb uas yuav tau xav txog yam xws li qhov xav tau qhov rooj profile, lub peev xwm ntau lawm thiab cov kev xav tau tshwj xeeb.