Tshiab zam tsim rau kev tsim cov khoom siv kov npo lub kaus mom hlau hlau ncej Profile C & Z Channel yob txoj kev tshuab Hoobkas nqe nrog ISO9001 / Ce / SGS / Soncap

Nrog rau cov lus qhia hauv siab no, peb tau txais kev txhim kho mus rau hauv ib qho ntawm cov thev naus laus zis tshiab tshaj plaws, tus nqi tsim nyog, thiab cov nqi sib tw rau Cov Khoom Siv Hluav Taws Xob Tshiab rau Cov Khoom Siv Hauv Tsev Kov Screen Lub kaus mom Sheet Hlau Ncej Profile C & Z Channel Roll Tsim Tshuab Hoobkas Nqe nrog ISO9001 / Ce / SGS / Soncap, Nco ntsoov xa peb koj cov kev qhia tshwj xeeb thiab cov kev xav tau, lossis kev paub tsis pub dawb los tiv tauj peb nrog cov lus nug lossis kev nug uas koj muaj.

Nrog rau cov lus qhia hauv siab no, peb tau txais kev txhim kho rau hauv ib qho ntawm cov thev naus laus zis tshiab tshaj plaws, tus nqi tsim nyog, thiab tus nqi sib tw rauTuam Tshoj yob txoj kev tshuab thiab sib sau tshuab, Peb vam tias peb tuaj yeem tsim kev koom tes ntev nrog txhua tus neeg siv khoom, thiab vam tias peb tuaj yeem txhim kho kev sib tw thiab ua tiav qhov kev sib tw yeej ua ke nrog cov neeg siv khoom.Peb zoo siab txais tos cov neeg siv khoom los ntawm thoob plaws lub ntiaj teb los tiv tauj peb rau txhua yam koj xav tau! Zoo siab txais tos txhua tus neeg muas zaub hauv tsev thiab txawv teb chaws tuaj xyuas peb lub Hoobkas.Peb vam tias yuav muaj kev sib tw ua lag luam nrog koj, thiab tsim kom muaj tag kis zoo dua.

KHOOM PLIG

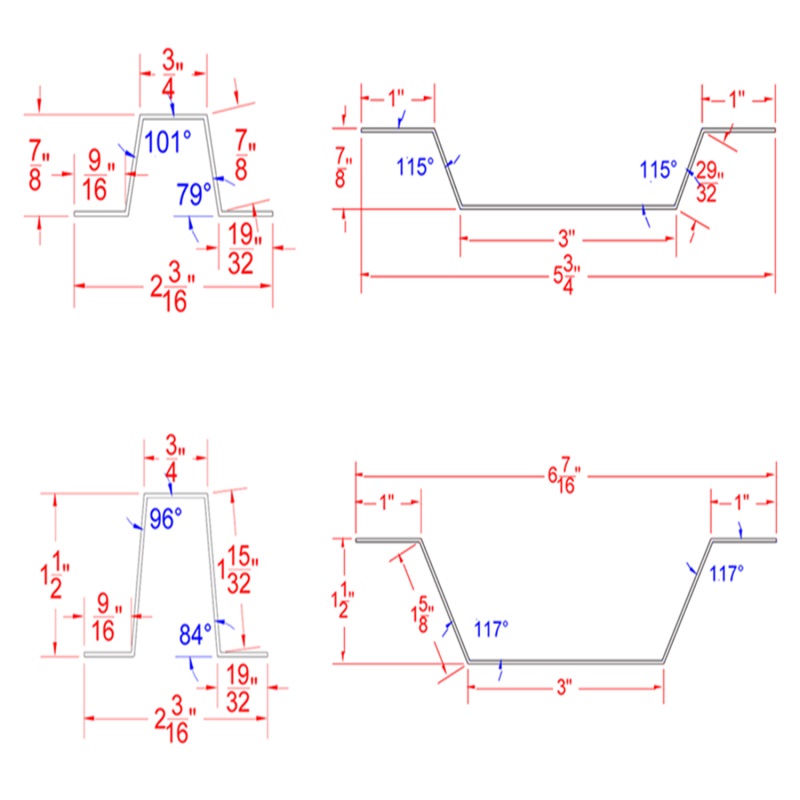

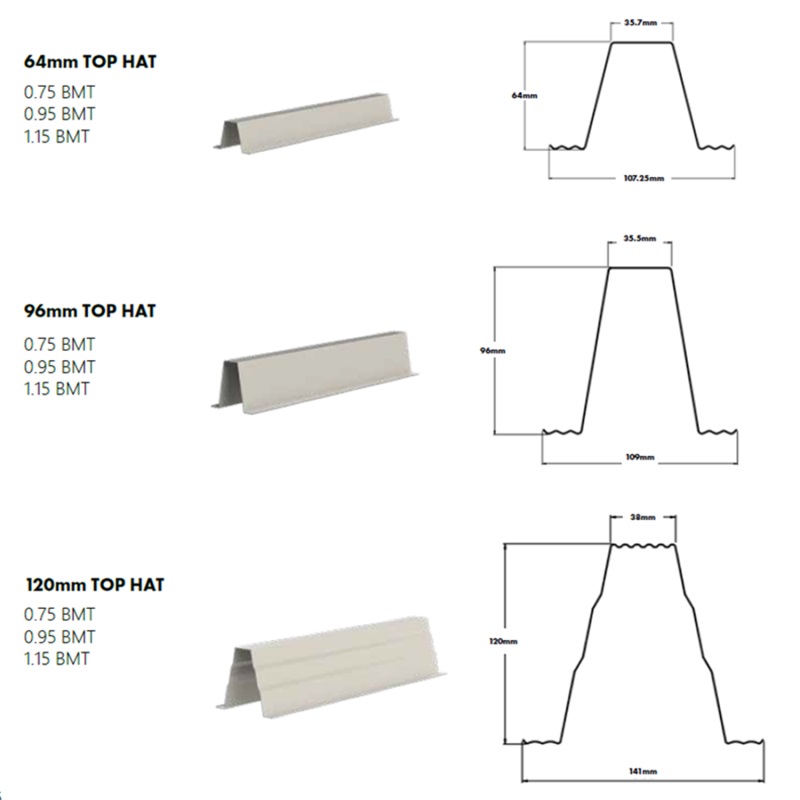

Lub kaus mom hlau yog lwm hom hlau ru tsev thav duab, uas tuaj yeem siv los ua purlin qhov twg qhov profile qis dua, lossis qhov chaw npog qhov yuav tsum tau ze dua purlin qhov sib nrug yog li ua tus qauv "Z" lossis "C" purlins kim heev.

Peb lub kaus mom profile yob txoj kev tshuab yog ua rau lub kaus mom raws, uas dav siv nyob rau hauv cov hlau / steel ru tsev kev lag luam.

MAIN TECHNICAL PARAMETERS

| 1 | Tshuab qauv | Tus kheej archway stands qauv |

| 2 | Tag nrho lub zog | Lub cev muaj zog - 18.5kw Hydraulic zog-5.5kw |

| 3 | Roller chaw nres tsheb | 18 dots chaw nres tsheb |

| 4 | Productivity | 15-25m / min |

| 5 | Decoiler | 3T hydraulic decoiler |

| 6 | Leverling ib feem | Upper yog 3 rollers, down yog 4 chaw nres tsheb (tag nrho yog 7 rollers) |

| 7 | Tsav system | Los ntawm kev ywj pheej gearbox |

| 8 | Txoj kab uas hla ntawm ncej | ¢ 60mm khoom ncej |

| 9 | Cov khoom siv rau cov menyuam | American D2 D3 |

| 10 | Pre xuas nrig ntaus & txiav system | Pre-txiav kom hloov cov khoom Khoom siv ntawm cov pwm pwm: Cr12 |

| 11 | Hydraulic txiav system | Cr12 nrog kev kho cua sov 58-60 ° |

| 12 | Hydraulic zog | 7.5 kWm |

TSEEM CEEB

| 1 | Tsis Siv Neeg De-coiler | 1. Tib lub taub hau tsim 2. Chaw thau khoom hnyav: 3Tons 3. Hydraulic tsis siv neeg expansion thiab zawm 4. Haum dav: <300mm 5. Coil ID: ¢ 500 ± 20mm 6. Coil OD: ≤1200mm |

| 2 | Servo Feeding Leveling | 1. Nws txais 5 rollers rau leveling, 2 khub ntawm phau ntawv rollers 2. Qhov siab tshaj plaws qib yob dav: 300mm 3. Kho kom haum rau qhov siab tshaj plaws yob tuab: 1 ~ 2mm 4. Kev ua haujlwm siab tshaj plaws: 20 m / min 5. Tsav: servo lub cev muaj zog |

| 3 | Multi-functional Punching Tshuab | 1.6 chaw nres tsheb xuas nrig ntaus, 2. Servo lub cev muaj zog: 1.3KW 3. Servo lub cev muaj zog hom: Nyiv Yaskawa 4. Haum dav: <300mm 5. Punching pwm ceev qhov chaw, rov ua dua. |

| 4 | Roll Forming Tshuab | 1. Tsav system: Tsav, reducer, kauv bevel iav tsav 2. Lub tshuab fais fab loj: 15KW * 2 Teeb, 3. Lub cev muaj zog hom: SIEMENS BADE servo lub cev muaj zog 4. Module Cheebtsam ceev positioning, rov ua dua 5. Tsim cov chaw nres tsheb: 18 pawg chaw nres tsheb |

| 5 | Hydraulic Tej Tshuab | 1. Hydraulic ib qho chaw nres tsheb, 2. Txiav quab yuam: 30Tons, 3. Txiav hom: nres txiav 4. Module Cheebtsam ceev positioning, rov ua dua |

| 6 | Computer Control Box | 1. Nyiv Mitsubishi motion controller PLC 2. Nyiv Yaskawa Servo System 3. Nrog tib neeg tshuab interface kov npo 4. Schneider tsis muaj zog tam sim no tswj |

| 7 | Chaw nres tsheb Hydraulic | 1. Hydraulic system zog: 15KW 2. Hydraulic nqi: Huade, 3. Nrog kiv cua txias system |

PRODUCTION PROCESS

Uncoiling → leveling → Looper (cia) → servo pub → Multi-stations punching → forming station → Hydraulic txiav → Cov khoom tiav tiav

KEV PAB CUAM

Lub kaus mom channel yob txoj kev tshuab; kaus mom profile txoj kev tshuab; kaus mom profile channel ua tshuab

Lub kaus mom channel steel yob txoj kev tshuab yog lub tshuab siv los tsim lub kaus mom channel steel lossis keel channel steel.Lub kaus mom channel yog cov hlau channel nrog lub kaus mom zoo li tus ntoo khaub lig-section uas feem ntau siv rau kev tsim thiab khi lub hom phiaj hauv kev tsim kho.Lub kaus mom channel yob txoj kev tshuab feem ntau muaj cov txheej txheem ntawm cov yob uas txuas ntxiv ua cov hlau sawb mus rau qhov xav tau lub kaus mom channel profile.Lub tshuab feem ntau muaj xws li uncoiler, pub chav tsev, yob txoj kev chaw nres tsheb, txiav tsev thiab tswj qhov system.

Zuag qhia tag nrho, lub kaus mom channel profile yob txoj kev tshuab yog yuav tsum-muaj cov cuab yeej rau cov tuam ntxhab thiab cov neeg cog lus hauv kev tsim kho thiab kev lag luam hlau.Nws muab cov kev daws teeb meem txhim khu kev qha thiab muaj txiaj ntsig zoo rau kev tsim cov khoom lag luam zoo nrog cov qhov ntev thiab cov duab zoo.