Tsawg MOQ rau Tuam Tshoj Hlau Sheet Cov Menyuam Ua Tshuab-Roof Vaj Huam Sib Luag Tshuab

Txhawm rau muab cov txiaj ntsig zoo rau koj thiab ua kom peb lub lag luam loj, peb kuj muaj cov kws tshuaj xyuas hauv QC Pab Pawg thiab paub tseeb tias peb cov kev pabcuam zoo tshaj plaws thiab cov khoom lag luam rau qis MOQ rau Tuam Tshoj Hlau Sheet Roller Forming Tshuab-Roof Vaj Huam Sib Luag Tshuab, Peb lub tuam txhab muaj kev tiv thaiv kev lag luam me ua ke. los ntawm qhov tseeb thiab kev ncaj ncees kom muaj kev sib raug zoo mus ntev nrog peb cov neeg siv khoom.

Txhawm rau muab cov txiaj ntsig zoo rau koj thiab nthuav peb txoj kev lag luam, peb kuj muaj cov neeg soj ntsuam hauv QC Pab Pawg thiab ua kom koj paub tseeb tias peb cov kev pabcuam zoo tshaj plaws thiab cov khoom lag luam rauTuam Tshoj Cold Roll Forming Tshuab, Xim pobzeb sib sau tshuab, Kev txiav txim siab yog txais tau nrog cov qib zoo sib txawv thiab cov neeg siv khoom tsim tshwj xeeb.Peb tau tos ntsoov los tsim kom muaj kev koom tes zoo thiab ua tiav hauv kev lag luam nrog cov lus ntev los ntawm cov neeg siv khoom thoob plaws ntiaj teb.

MAIN TECHNICAL PARAMETERS

| Hlau phaj | Q345B 610L |

| Sab nraud txoj kab uas hla ntawm steel kauj | ≤Φ1800 hli |

| Sab hauv txoj kab uas hla ntawm steel kauj | F610mm |

| Hlau siv dav | Max 600 hli |

| Sawb thickness | 6 ~ 12mm |

| Ib yob hnyav | ≤10000kg |

PRODUCTION PROCESS

Cov kab ntau lawm yog ua raws li cov txheej txheem hauv qab no:

Uncoiling → Pub Thiab Leveling → Txiav, Nias, Vuam → Roll Forming → Txiav → Tawm

MAIN COMPONENTS

| Ua tshuab | 1set ib |

| Uncoiler | 1set ib |

| Leveling | 1set ib |

| Shear taub qab vuam | 1set ib |

| Tshuab txoj kev | 1set ib |

| tshuab shearing | 1set ib |

| Discharge ntaus ntawv | 1set ib |

1. Hluav taws xob tswj qhov system

Tag nrho cov kab yog tswj los ntawm Nyiv Mitsubishi PLC.Lub cev muaj zog ntawm lub tshuab yob txoj kev siv lub tshuab DC lub cev muaj zog, uas yog tswj los ntawm cov khoom siv digital DC ceev tswj, nrog rau kev teeb tsa ceev thiab lub tswb tsis raug.

2. Hydraulic system

Muaj ob lub tshuab hydraulic nyob rau hauv tag nrho cov kab, txhua tus nrog ib txheej ntawm welded roj tank, plunger twj tso kua mis, hydraulic valve thaiv thiab valve thaiv, roj lim, roj txias system thiab pipeline.

1) Cov roj twj tso kua mis siv lub npe nrov hauv tsev CY series siab siab axial piston twj tso kua mis;

2) Lub valve thaiv ntawm no hydraulic system txais ib lub phaj-hom integrated qauv;

3) Lub siab tswj valve, kev tswj lub ntsiab lus, ntws tswj lub ntsiab lus thiab lwm yam tseem ceeb tswj lub ntsiab ntawm cov hydraulic system no yog tag nrho cov khoom siv high-pressure imported;

4) Lub tog raj kheej roj tau txais cov khoom lag luam zoo hauv lub npe thiab cov ntsaws ruaj ruaj los tiv thaiv kev xau

KEV PAB CUAM

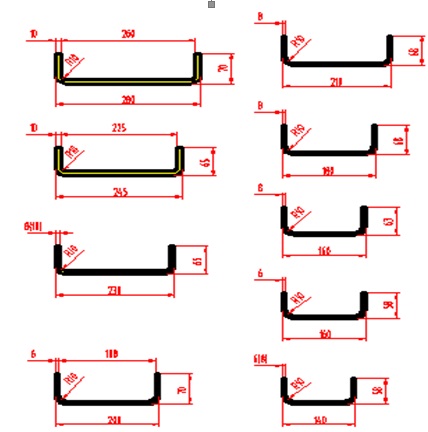

Lub u beam yob txoj kev tshuab yog tsuas yog siv los tsim cov qauv steel hauv qab ntawm lub tsheb.

APPLICATION

Tsheb girder daim hlau yog tsuas yog siv los tsim tsheb ntev kab teeb, hla kab, pem hauv ntej thiab nram qab qag, bumpers thiab lwm yam khoom siv.

Txhawm rau muab cov txiaj ntsig zoo rau koj thiab ua kom peb lub lag luam loj, peb kuj muaj cov kws tshuaj xyuas hauv QC Pab Pawg thiab paub tseeb tias peb cov kev pabcuam zoo tshaj plaws thiab cov khoom lag luam rau qis MOQ rau Tuam Tshoj Hlau Sheet Roller Forming Tshuab-Roof Vaj Huam Sib Luag Tshuab, Peb lub tuam txhab muaj kev tiv thaiv kev lag luam me ua ke. los ntawm qhov tseeb thiab kev ncaj ncees kom muaj kev sib raug zoo mus ntev nrog peb cov neeg siv khoom.

Tsawg MOQ rauTuam Tshoj Cold Roll Forming Tshuab, Xim pobzeb sib sau tshuab, Kev txiav txim siab yog txais tau nrog cov qib zoo sib txawv thiab cov neeg siv khoom tsim tshwj xeeb.Peb tau tos ntsoov los tsim kom muaj kev koom tes zoo thiab ua tiav hauv kev lag luam nrog cov lus ntev los ntawm cov neeg siv khoom thoob plaws ntiaj teb.