IOS Certificate High Speed 2/3 Wave Highway Fence Guardrail Roll Forming Machine

Lub tuam txhab ua rau lub tswv yim ua haujlwm "kev tswj hwm kev tshawb fawb, kev ua tau zoo thiab kev ua haujlwm zoo tshaj plaws, cov neeg siv khoom zoo tshaj plaws rau IOS Daim Ntawv Pov Thawj Kev Kub Ceev 2/3 Wave Highway Fence Guardrail Roll Forming Tshuab, Peb tab tom nrhiav rau pem hauv ntej los tsim kev lag luam mus sij hawm ntev kev lag luam koom nrog thoob ntiaj teb. cov neeg yuav khoom.

Lub tuam txhab ua rau lub tswv yim ua haujlwm "kev tswj xyuas kev tshawb fawb, kev ua haujlwm siab thiab kev ua haujlwm zoo, cov neeg siv khoom zoo tshaj plaws rauTuam Tshoj Highway laj kab Guardrail yob txoj kev tshuab thiab tsoo Barrier yob txoj kev tshuab, Tam sim ntawd thiab cov kws tshaj lij tom qab muag kev pabcuam muab los ntawm peb pawg kws pab tswv yim tau zoo siab rau peb cov neeg yuav khoom.Cov ncauj lus kom ntxaws thiab cov kev txwv los ntawm cov khoom muag yuav raug xa tuaj rau koj rau txhua qhov kev lees paub.Cov qauv dawb tuaj yeem xa tuaj thiab lub tuam txhab tshawb xyuas rau peb lub tuam txhab.n Morocco rau kev sib tham yog txais tos tas li.Cia siab tias yuav tau txais cov lus nug ntaus koj thiab tsim kom muaj kev sib koom tes ua haujlwm ntev.

MAIN TECHNICAL PARAMETERS

Khoom siv: Galvanized Sheet

Tawm lub zog ntawm raw khoom: 235Mpa

Coil sab nraud: ≤Ф1200mm

Coil Inner Diameter: Ф508mm

Hlau Sawb Dav: ≤150mm

Hlau Sawb Thickness: 2mm

Coil Nyhav: ≤2000 kg

Tshuab Pem Teb Thaj Chaw: 25000X3000X1800

PRODUCTION PROCESS

Cov kab ntau lawm yog ua raws li cov txheej txheem hauv qab no::

Uncoiling → Leveling Servo pub → Punching → Cold Roll Forming → Hydraulic Shearing → Khoom Siv Tawm

MAIN COMPONENTS

1. Uncoiler 1set

Tso cai coil sab hauv txoj kab uas hla: Ф508

Max.tso cai coil sab nraud txoj kab uas hla: Ф1200mm

Max.tso cai yob dav: 200 mm

Max.yob nqa hnyav: ≤2000 kg

2. Servo pub 1 teeb

Qhov siab tshaj plaws pub ceev: 30m / min

Qhov siab tshaj plaws pub pub dawb: ≤200mm

Tso cai pub noj thickness ≤ 2mm

Kev pub mis ib leeg yuam kev: ≤ ± 0.2mm (qhov kam rau ua tsis suav nrog)

Servo lub cev muaj zog hom: Yaskawa (YASKAWA, Nyiv)

Servo lub cev muaj zog: ≈ 3Kw (raws li qhov kawg tsim)

3. Punching Tshuab 1set

Nws txais cov kua plaub-kem xovxwm hom, uas yog kev lag luam, siv tau thiab nrawm.Lub punching nrug yog adjustable nyob rau hauv lub transverse kev taw qhia ntawm lub phaj, thiab lub punching kauj ruam yuav hloov tau los ntawm cov hluav taws xob tswj system.

4. Roller Forming Tshuab 1 teeb

Archway khoom: QT450.

Cov khoom siv ncej: 40Cr, quenched thiab tempered, hardness yog HRC45 ~ 50

Daim ntawv hla tebchaws: 12 kis

Ncej txoj kab uas hla ntawm kev sib sau tshuab: φ60mm (raug tsim kawg)

Lub cev muaj zog: txog 30kW (raws li qhov kawg tsim)

Maximum linear ceev: 3 ~ 10m / min

5. Pneumatic taug qab shearing 1 teeb

Cutter khoom: Cr12MoV (hardness tom qab quenching yog HRC58 ~ 62)

6. Hydraulic System 1 teeb

Lub ntsiab Cheebtsam yog: roj twj tso kua mis, lub cev muaj zog, hydraulic valve, solenoid valve, lim thiab hydraulic roj tank, thiab lwm yam.Lub hydraulic system siv lub lim, thiab qhov huv ntawm cov roj yog guaranteed nyob rau theem 6-8.

MAIN ELECTRICAL COMPONENTS

| No | Cov khoom npe | Hom |

| 1 | PLC | Mitsubishi, Nyiv |

| 2 | Servo Tsav | Yaskawa, Nyiv |

| 3 | Inverter | Delta (Taiwan, Suav teb) |

| 4 | Kov npo | Vinylon (Taiwan, Suav teb) |

| 5 | Tsawg-voltage hluav taws xob Cheebtsam | Omron |

KEV PAB CUAM

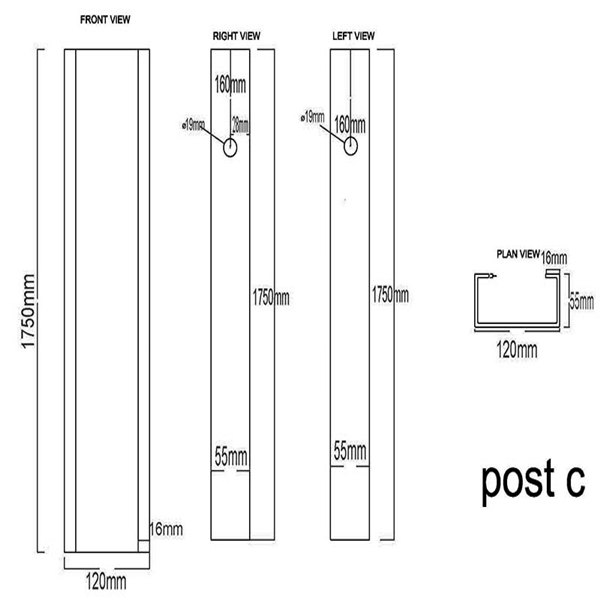

C-profile forming tshuab rau txoj kev loj guardrail yog cov cuab yeej tshwj xeeb rau kev tsim C-shaped profiles rau txoj kev loj guardrail.Cov profiles no yog ib qho tseem ceeb hauv kev muab kev nyab xeeb thiab kev tiv thaiv rau cov tsheb taug kev ntawm txoj kev loj.

Lub tshuab yob txoj kev muaj cov txheej txheem ntawm cov chais uas ua rau cov hlau txuas ntxiv mus rau qhov xav tau C-zoo li profile.Lub tshuab tuaj yeem tswj thiab kho qhov dav, qhov siab thiab tuab ntawm cov profiles raws li qhov xav tau tshwj xeeb.

Cov txheej txheem pib los ntawm kev pub ib yob ntawm cov hlau sawb rau hauv lub tshuab, uas yog tom qab ntawd dhau los ntawm cov txheej txheem ntawm cov chais, uas maj mam khoov thiab tsim cov hlau sawb rau hauv C-profile.Thaum lub sij hawm cov txheej txheem no, rollers siv siab los xyuas kom meej tias qhov profile khaws nws cov duab thiab loj.Roll forming machines feem ntau automated thiab tuaj yeem khiav ntawm kev kub ceev kom ua tau zoo tsim kev loj guardrail profiles.Nws yog tsim los rau kev tsim khoom tas mus li thiab muaj kev nyab xeeb los xyuas kom muaj kev noj qab haus huv ntawm tus neeg teb xov tooj.

Zuag qhia tag nrho, txoj kev loj guardrail C profile forming tshuab plays lub luag haujlwm tseem ceeb hauv kev tsim khoom ntawm txoj kev loj guardrail, uas tuaj yeem ua tau zoo thiab raug tsim cov C profile uas yuav tsum tau muaj rau kev nyab xeeb thiab kev tiv thaiv tsheb ntawm txoj kev.