Lub koob npe nrov Tuam Tshoj 2 nyob rau hauv 1 Ob Chav Decker Profile Sheet Roof Panel Roll Forming Tshuab rau muag

Muab tag nrho cov luag num kom tau raws li txhua qhov kev xav tau ntawm peb cov neeg siv khoom;ua kom tiav kev nce qib tsis tu ncua los ntawm kev txhawb nqa kev nce qib ntawm peb cov neeg siv khoom;dhau los ua tus neeg koom tes zaum kawg ntawm cov neeg siv khoom thiab ua kom muaj kev txaus siab ntawm cov neeg yuav khoom rau lub koob npe nrov Tuam Tshoj 2 hauv 1 Ob Chav Decker Profile Sheet Roof Panel Roll Forming Tshuab rau muag, Rau cov khoom siv roj vuam zoo & txiav cov khoom siv raws sijhawm thiab ntawm tus nqi tsim nyog , koj tuaj yeem suav rau lub koom haum lub npe.

Muab tag nrho cov luag num kom tau raws li txhua qhov kev xav tau ntawm peb cov neeg siv khoom;ua kom tiav kev nce qib tsis tu ncua los ntawm kev txhawb nqa kev nce qib ntawm peb cov neeg siv khoom;dhau los ua qhov kawg kev koom tes ruaj khov ntawm cov neeg siv khoom thiab ua kom cov neeg siv khoom txaus siab rau2 hauv 1 Ob Chav Txheej Tshuab, Tuam Tshoj Ob Chav Decker Roll Forming Tshuab, Peb lub hom phiaj yog kom xa cov nqi zoo tshaj plaws rau peb cov neeg siv khoom thiab lawv cov neeg siv khoom.Qhov kev cog lus no permeates txhua yam peb ua, tsav peb txuas ntxiv txhim kho thiab txhim kho peb cov khoom thiab cov txheej txheem kom ua tiav koj cov kev xav tau.

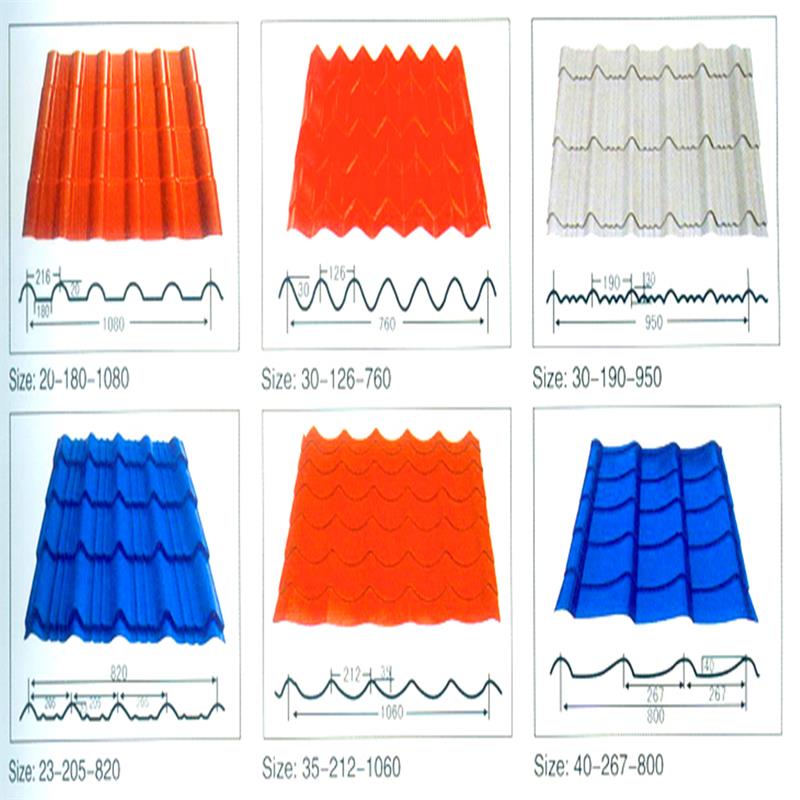

KHOOM PLIG

Qhov no glazed pobzeb yob txoj kev tshuab yog siv los ua cov pobzeb glazed, uas yog dav siv nyob rau hauv factories, tsev, tsev so, villas thiab lwm yam industrial thiab civil vaj tse.

MAIN PARAMETERS

Khoom siv: Galvanized ntawv

Tawm lub zog ntawm cov ntaub ntawv raw: ≤235Mpa

Tensile zog ntawm raw cov ntaub ntawv: ≤550Mpa

Sab nraud txoj kab uas hla: ≤Ф1300mm

Inner Diameter ntawm Coils: Ф508

Hlau pluaj dav: ≤1000mm

Hlau hlua Thickness: 0.2 ~ 0.4mm

Luj / Coil: ≤5000 kg

PRODUCTION PROCESS

Glazed vuas manufacturing tshuab khoom yog ua raws li cov txheej txheem hauv qab no:

Uncoiling → Looper (Storage) → Cold forming → Pressing Table & Cutting → Discharging

MAIN COMPONENTS & Specification

| No | Cov khoom npe | Specifications |

| 1 | Decoiler | Phau ntawv hom;Coils ID: Ф508mm;Coil OD: Ф1300mm;Coil Dav: 1000mm;Coil hnyav: ≤5000 kg |

| 2 | Roll Forming Tshuab | Lub tshuab tsim yog tsav los ntawm lub cev muaj zog, reducer thiab sub-reducer.Moulding tshuab memorial arch rau kev ywj pheej memorial arch qauv (tsis yog - phaj qauv), kev ua haujlwm ruaj khov, txhim khu kev qha, siab precision.Lub hauv paus yog welded steel qauv.Annealing tom qab vuam.Lub molding cov menyuam yog tsim los ntawm kev software, thiab cov khoom yog ua los ntawm zoo 45 steel thiab nyuaj chrome plating.Daim ntawv hla tebchaws: 16 kis (kwv yees rau qhov kawg tsim);Ncej txoj kab uas hla: φ70mm (raws li qhov kawg tsim);Lub cev muaj zog: 5.5kw Qhov siab tshaj plaws linear ceev: 2 ~ 5 m / min |

| 3 | Hydraulic Txiav | Cutter hom adopts tsis muaj seem txiav.Cutter khoom: Cr12MoV (hardness yog HRC58 ~ 62 tom qab quenching);Kev ntsuas qhov tseeb: ± 1.5mm |

| 7 | Hluav taws xob tswj txee | PLC: Mitsubishi;Inverter: Delta;Kov npo: Vinylon (Taiwan, Tuam Tshoj);Cov khoom siv hluav taws xob tsawg: Schneider (Fabkis);Encoder: Omron (Nyiv) |

| 8 | Hydraulic System | Hydraulic system siv lim, kev huv ntawm cov roj kom ntseeg tau qib 6-8 |

KEV PAB CUAM

Glazed pobzeb yob txoj kev tshuab; glazed vuas manufacturing tshuab; glazed pobzeb txoj kev tshuab

Muab tag nrho cov luag num kom tau raws li txhua qhov kev xav tau ntawm peb cov neeg siv khoom;ua kom tiav kev nce qib tsis tu ncua los ntawm kev txhawb nqa kev nce qib ntawm peb cov neeg siv khoom;dhau los ua tus neeg koom tes zaum kawg ntawm cov neeg siv khoom thiab ua kom muaj kev txaus siab ntawm cov neeg yuav khoom rau lub koob npe nrov Tuam Tshoj 2 hauv 1 Ob Chav Decker Profile Sheet Roof Panel Roll Forming Tshuab rau muag, Rau cov khoom siv roj vuam zoo & txiav cov khoom siv raws sijhawm thiab ntawm tus nqi tsim nyog , koj tuaj yeem suav rau lub koom haum lub npe.

Lub koob npe nrovTuam Tshoj Ob Chav Decker Roll Forming Tshuab, 2 hauv 1 Ob Chav Txheej Tshuab, Peb lub hom phiaj yog kom xa cov nqi zoo tshaj plaws rau peb cov neeg siv khoom thiab lawv cov neeg siv khoom.Qhov kev cog lus no permeates txhua yam peb ua, tsav peb txuas ntxiv txhim kho thiab txhim kho peb cov khoom thiab cov txheej txheem kom ua tiav koj cov kev xav tau.