High Quality Tag Nrho Tsis Siv Neeg Galvanized Steel Lub Teeb Ntsuas Hlau Framing Txias Roll / Rolling Forming / Yav Dhau Los Ua Tshuab

Peb lub hom phiaj yog los muab cov khoom lag luam zoo tshaj plaws thiab cov kev daws teeb meem ntawm cov nqi sib tw, thiab kev txhawb nqa zoo tshaj plaws rau cov neeg siv khoom thoob ntiaj teb.Peb tau ISO9001, CE, thiab GS tau ntawv pov thawj thiab nruj me ntsis raws li lawv cov specifications zoo rau High Quality Tag Nrho Tsis Siv Neeg Galvanized Steel Lub Teeb Gauge Steel Framing Txias Rolling / Rolling Forming / Yav Tom Ntej Ua Tshuab, Peb yuav ua peb qhov zoo tshaj plaws kom tau raws li cov neeg siv khoom xav tau. nrog cov khoom zoo tshaj plaws, cov tswv yim siab heev, thiab cov tuam txhab tsim khoom thiab sijhawm.Peb txais tos txhua tus neeg siv khoom.

Peb lub hom phiaj yog los muab cov khoom lag luam zoo tshaj plaws thiab cov kev daws teeb meem ntawm cov nqi sib tw, thiab kev txhawb nqa zoo tshaj plaws rau cov neeg siv khoom thoob ntiaj teb.Peb tau ISO9001, CE, thiab GS ntawv pov thawj thiab nruj me ntsis raws li lawv cov specifications zoo rauTuam Tshoj yob txoj kev tshuab thiab txias yob txoj kev tshuab, Tam sim no peb muaj ib pab neeg muag khoom tsim nyog, lawv tau ua tiav cov txheej txheem thev naus laus zis zoo tshaj plaws thiab cov txheej txheem tsim khoom, muaj kev paub ntau xyoo hauv kev muag khoom txawv teb chaws, nrog cov neeg siv khoom tuaj yeem sib txuas lus seamlessly thiab raug nkag siab txog cov kev xav tau tiag tiag ntawm cov neeg siv khoom, muab cov neeg siv khoom nrog cov kev pabcuam tshwj xeeb thiab tshwj xeeb. cov khoom.

KHOOM PLIG

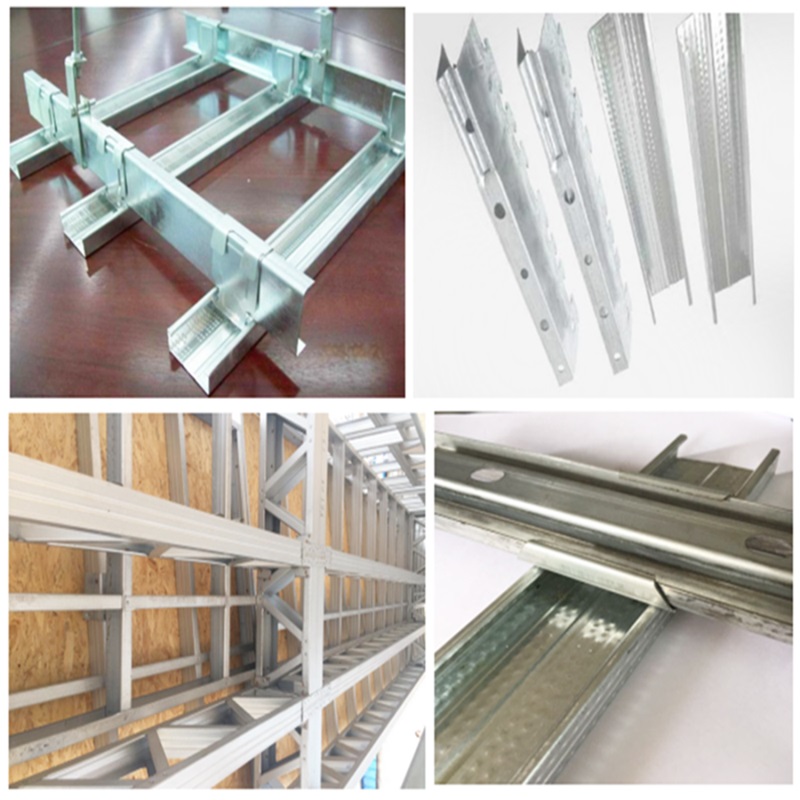

Lub teeb steel keel ntau lawm kab siv los tsim "villa keel".Lub teeb steel villa tsim tshuab nyeem tag nrho cov keel tivthaiv qauv tsim los ntawm Vertex BD software los ntawm U disk, thiab laps lawv ua ke los tsim ib lub teeb steel villa ua tiav.

Cov kab ntau lawm no tau nthuav dav daim ntawv thov, feem ntau suav nrog: cov tsev ntiav, tsev neeg ib leeg, tsev so nthuav qhia, tsev so tsheb;Roll-formed nyias-walled lub teeb-steel qauv vaj tse xws li vaj tse, modular tsev, coj mus muag thiab kev lag luam vaj tse, nrog rau cov vaj tse rau kev kub ntxhov thiab kev puas tsuaj, kev puas tsuaj, thiab tom qab kev puas tsuaj rov tsim tsev.

MAIN PARAMETERS

| No | Cov khoom | Specification |

| 1 | Qauv | SART-C89 |

| 2 | Coil OD | 1300 hli |

| 3 | Coil ID | 450-530 hli |

| 4 | Coil Thickness | 0.8-1.2 hli |

| 5 | Nqa Nyhav | 3 ton |

| 6 | Tsim Daim Ntawv Pov Thawj | 8 dots |

| 7 | Ntau lawm ceev | 0-15m / min |

| 8 | Tshuab fais fab | 15 KW |

| 9 | Npog Qhov Chaw | 12000 * 2000 * 1800 hli |

PRODUCTION PROCESS

Uncoiling → Leveling → Punching → Roll Forming → Txiav → Discharge

MAIN COMPONENTS

| No | Cov khoom | Qty | Main Parameters |

| 1 | Uncoiler | 1set ib | 1. Tsav hom: lub cev muaj zog tsav yog nres ntaus ntawv yog 2. Nqa hnyav: 3 tons 3. Sab hauv txoj kab uas hla: 450–530 mm 4. Qhov siab tshaj plaws sab nraud: 1300 mm 5. Lwm yam nta: tsis siv neeg pub mis. |

| 2 | Leveling Feeder | 1set ib | Qhov kev pub mis yog qhov tseeb yam tsis muaj kev ua siab ntev |

| 3 | 80T Punching xovxwm | 1set ib | Lub tshuab hydraulic ntawm lub tshuab xuas nrig ntaus no tshwj xeeb tsim rau ntau lub chaw nres tsheb xuas nrig ntaus tshuab.Lub tshuab hydraulic txais lub twj tso kua mis thiab accumulator tswj hom, thiab siv tshwj xeeb hydraulic tswj module. |

| 4 | Roll Forming Tshuab | 1set ib | 1. No.of forming roller sets: 8 sets, 4 sets of fine adjustment rollers 2.Transmission hom: iav + saw 3. Cov khoom siv / hom: Cr12MoV 4. Pa molding ceev: 50m / min 5. ntev kam rau ua: 0.5 hli; ncaj siab kam rau ua: 0.3 hli |

| 5 | Hydraulic Tej Tshuab | 1set ib | Cutter khoom: Cr12MoV (hardness tom qab quenching yog HRC58 ~ 62) |

KEV PAB CUAM

Lub teeb tiav steel keel yog ib yam tshiab ntawm cov khoom siv hauv tsev, uas muaj cov yam ntxwv ntawm lub teeb yuag, loj span, zoo cuam tshuam kev ua tau zoo, thiab zoo structural seismic kev ua tau zoo.

LGSF tshuab; lub teeb gauge yob txoj kev tshuab; lub teeb steel keel yob txoj kev tshuab

Lub teeb steel keel txoj kev tshuab yog lub tshuab siv los tsim lub teeb steel keels rau ntau yam kev siv.Keels yog tsim los ntawm kev dhau ib txoj hlua ntawm cov hlau los ntawm cov txheej txheem ntawm cov chais uas maj mam ua nws rau hauv qhov xav tau profile.

Lub tshuab yog tsim los ua cov txheej txheem ntau hom hlau xws li steel, aluminium, tooj liab thiab lwm yam.Keels ntawm ntau yam duab thiab qhov ntau thiab tsawg tuaj yeem ua raws li engineering xav tau.

Roll forming machines feem ntau yog automated nrog kev tswj uas tso cai rau tus neeg teb xov tooj los kho qhov ceev thiab siab ntawm cov yob kom ua tiav qhov xav tau.Lub resulting studs yog ncaj, uniform thiab zoo ib yam, zoo tagnrho rau kev tsim kho tej yaam num.