Factory ncaj qha Kev Ua Haujlwm Zoo Ua Haujlwm Cuz Zoo Sib Sau Ua Si Hloov Yob Txoj Tshuab rau Hlau Hlau

Mob siab rau kev tswj hwm zoo heev thiab xav txog lub tuam txhab cov neeg yuav khoom, peb cov neeg ua haujlwm paub txog cov neeg koom tes feem ntau muaj los tham txog koj cov kev xav tau thiab ua rau cov neeg yuav khoom txaus siab rau lub Hoobkas ncaj qha Zoo Ua Haujlwm Zoo Ua Haujlwm Cuz Shape Forming Fast Hloov Roll Forming Tshuab rau Hlau Hlau, Peb txais tos cov neeg yuav khoom txhua qhov chaw. nyob rau hauv lo lus hu rau peb mus ntev khiav lag luam koom haum me me.Peb cov kev daws teeb meem yog cov saum toj kawg nkaus.Ib zaug xaiv, Zoo heev mus ib txhis!

Kev mob siab rau kev tswj hwm zoo heev thiab xav txog lub tuam txhab cov neeg yuav khoom, peb cov neeg ua haujlwm paub txog cov neeg koom tes feem ntau muaj los tham txog koj qhov kev xav tau thiab ua rau txhua tus neeg yuav khoom txaus siab rauTuam Tshoj Czu Ceev Hloov Rolls Tshuab thiab Czu Internal Txauv Rollers Ua Tshuab, Peb tau yeej lub koob npe nrov ntawm cov neeg siv khoom txawv teb chaws thiab hauv tsev.Ua raws li kev tswj hwm txoj cai ntawm "qhib taw qhia, cov neeg siv khoom ua ntej, kev ua haujlwm siab thiab kev pabcuam loj", peb zoo siab tos txais cov phooj ywg los ntawm txhua qhov chaw ntawm lub neej los koom tes nrog peb.

MAIN TECHNICAL PARAMETERS

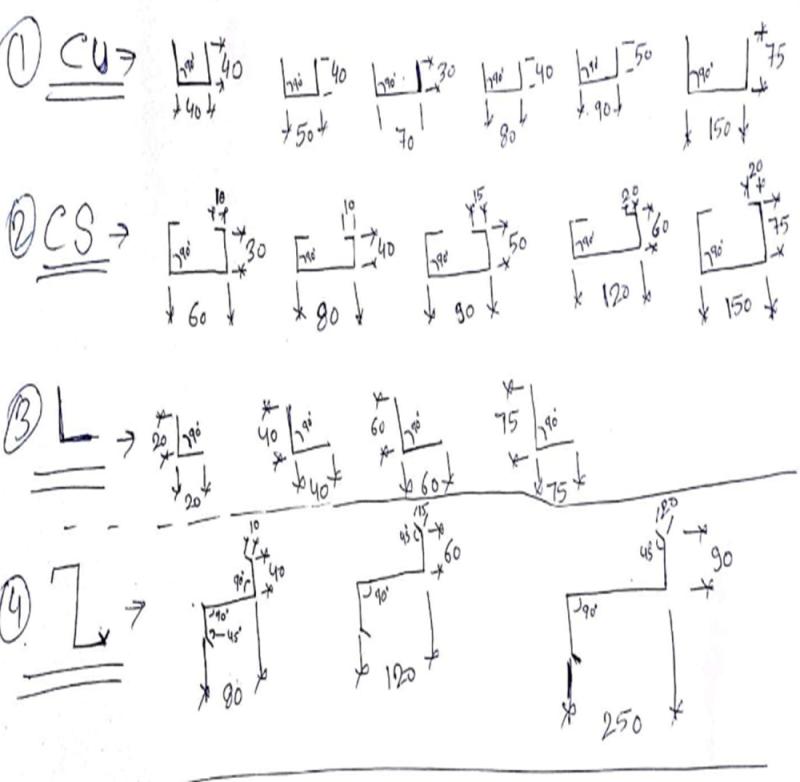

| Profile | Web | Flange | Daim di ncauj | Thickness |

| C | 80-300 hli | 40-80 hli | 10-25 hli | 1.2-3.2 hli |

| Z | 120-300 hli | 40-80 hli | 10-25 hli | 1.2-3.2 hli |

Kev hloov pauv ceev ceev

PRODUCTION PROCESS

Uncoiling → Leveling → Looper (Cov Khoom Siv Cia) → Servo Pub → Multi-Station Punching Tshuab (Txiav Tawm) → Roll Forming Machine → Cov khoom tiav

MAIN COMPONENTS

Cov kab ntau lawm no yog tsim los ntawm cov hauv qab no:

| No | Cov khoom npe | Specifications |

| 1 | Decoiler | Tib lub taub hau hom, ib qho kev txhawb nqa;Coils ID: Ф508mm;Coil OD: Ф1200mm;Coil Dav: 500mm;Coil hnyav: ≤5000 kg; |

| 2 | Tshuab Leveling | 5 roller leveling;Max.ceev: 20m / min;Max.Leveling dav: 500mm;Max.Coil thickness: 1 ~ 3 hli;Lub zog ntawm leveling tshuab: approx.7.5kw (raws li qhov kawg tsim) |

| 3 | Servo Feeder | Qhov siab tshaj plaws pub ceev: 30m / min;Qhov siab tshaj plaws pub dav: ≤500mm;Tso cai pub thickness: ≤3mm;Precision ntawm pub: ± 0.2mm / kauj ruam;Servo lub cev muaj zog: Nyiv, Yaskawa;Servo lub cev muaj zog: kwv yees li 4.4KW (raws li qhov kawg tsim) |

| 4 | Multi-Punching | Txhawm rau ua kom tiav cov punching qhov ntawm qhov profile. |

| 5 | Ceev Hloov Roll Forming Tshuab | Muaj ob hom txiv ntoo nyob rau sab nraud ntawm lub archway: sab laug (sab laug) thiab sab xis (sab sauv).Archway khoom: QT450.8/13 Cov ntaub ntawv hais lus;Cov khoom siv ncej: 40Cr, quenched thiab tempered, hardness yog HRC45 ~ 50;Parameters: Forming passes: 36 passes (txuas mus rau qhov kawg tsim);Archway sorties: 36 + 32 = 68 sorties;Ncej txoj kab uas hla ntawm kev sib sau tshuab: φ70mm (raug tsim kawg);Lub cev muaj zog: 55kw;Maximum linear ceev: 2 ~ 8m / min |

| 6 | Hydraulic Txiav | Hom cutter adopts blanking shearing;Hniav khoomBlade khoom: Cr12MoV (hardness tom qab quenching HRC58 ~ 62);Parameter: txiav qhov tseeb: ± 1.5mmAccuracy: ± 1.5mm |

| 7 | Hluav taws xob tswj txee | PLC: Mitsubishi;Inverter: Delta;Kov npo: Vinylon (Taiwan, Tuam Tshoj);Cov khoom siv hluav taws xob tsawg: Schneider (Fabkis);Encoder: Omron (Nyiv);Servo maub los: Yaskawa (Nyiv) |

| 8 | Hydraulic System | Hydraulic system siv lim, kev huv ntawm cov roj kom ntseeg tau qib 6-8 |

KEV UA HAUJ LWM NTAWM TILE MAKING MACHINE

CZ ceev hloov yob txoj kev tshuab kab;CZUL ceev hloov yob txoj kev tshuab;c purlin ceev hloov yob txoj kev tshuab;CZ Purlin yob txoj kev tshuab

Mob siab rau kev tswj hwm zoo heev thiab xav txog lub tuam txhab cov neeg yuav khoom, peb cov neeg ua haujlwm paub txog cov neeg koom tes feem ntau muaj los tham txog koj cov kev xav tau thiab ua rau cov neeg yuav khoom txaus siab rau lub Hoobkas ncaj qha Zoo Ua Haujlwm Zoo Ua Haujlwm Cuz Shape Forming Fast Hloov Roll Forming Tshuab rau Hlau Hlau, Peb txais tos cov neeg yuav khoom txhua qhov chaw. nyob rau hauv lo lus hu rau peb mus ntev khiav lag luam koom haum me me.Peb cov kev daws teeb meem yog cov saum toj kawg nkaus.Ib zaug xaiv, Zoo heev mus ib txhis!

Hoobkas ncaj qhaTuam Tshoj Czu Ceev Hloov Rolls Tshuab thiab Czu Internal Txauv Rollers Ua Tshuab, Peb tau yeej lub koob npe nrov ntawm cov neeg siv khoom txawv teb chaws thiab hauv tsev.Ua raws li kev tswj hwm txoj cai ntawm "qhib taw qhia, cov neeg siv khoom ua ntej, kev ua haujlwm siab thiab kev pabcuam loj", peb zoo siab tos txais cov phooj ywg los ntawm txhua qhov chaw ntawm lub neej los koom tes nrog peb.