2019 Zoo Zoo Tuam Tshoj High Precision Telescopic Channel Drawer Slide Rail Yob txoj kev tshuab nrog hloov ceev

Nrog rau cov thev naus laus zis thiab cov chaw tsim khoom, kev tswj xyuas zoo, tsim nyog tus nqi, lub tuam txhab tshwj xeeb thiab kev sib koom tes nrog kev cia siab, peb tau mob siab rau muab qhov zoo tshaj plaws tsim nyog rau peb cov neeg siv khoom rau 2019 Zoo Zoo Tuam Tshoj High Precision Telescopic Channel Drawer Slide RailRoll Forming TshuabNrog Kev Hloov Ceev, Peb lub hom phiaj yog ib txwm tsim kom muaj Win-win scenario nrog peb cov neeg siv khoom.Peb xav tias peb yuav yog koj qhov kev xaiv loj tshaj plaws."Reputation Pib nrog, Cov Neeg Yuav Khoom Ua Ntej.“Tsav koj qhov kev nug.

Nrog rau cov thev naus laus zis thiab cov chaw tsim khoom, kev tswj xyuas zoo, tsim nyog tus nqi, lub tuam txhab tshwj xeeb thiab kev sib koom tes nrog cov zeem muag, peb tau mob siab rau muab qhov zoo tshaj plaws tsim nyog rau peb cov neeg siv khoom.Tuam Tshoj Cold Roll Forming Tshuab, Roll Forming Tshuab, Peb cov neeg ua haujlwm muaj kev paub dhau los thiab kev cob qhia nruj me ntsis, nrog kev paub tshwj xeeb, nrog lub zog thiab ib txwm hwm lawv cov neeg siv khoom raws li No. 1, thiab cog lus tias yuav ua lawv qhov zoo tshaj plaws los muab cov kev pabcuam zoo thiab tus kheej rau cov neeg siv khoom.Lub Tuam Txhab them nyiaj rau kev tswj hwm thiab txhim kho kev sib raug zoo nrog cov neeg siv khoom mus sij hawm ntev.Peb cog lus tias, raws li koj tus khub zoo tshaj plaws, peb yuav txhim kho lub neej yav tom ntej thiab txaus siab rau cov txiv hmab txiv ntoo uas txaus siab ua ke nrog koj, nrog rau kev mob siab rau, tsis muaj zog thiab lub siab xav mus tom ntej.

QHOV TSEEB

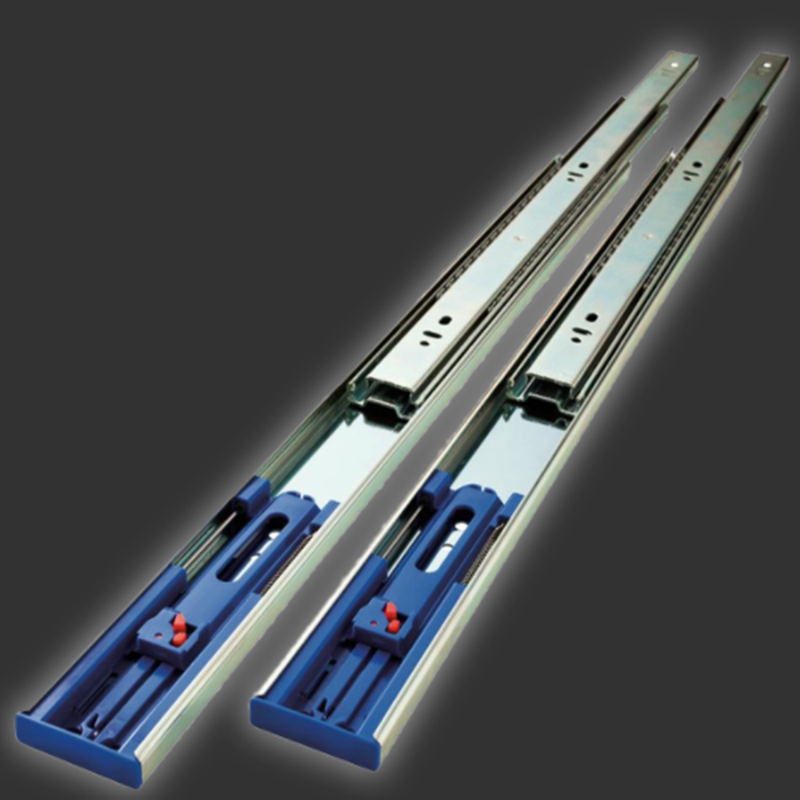

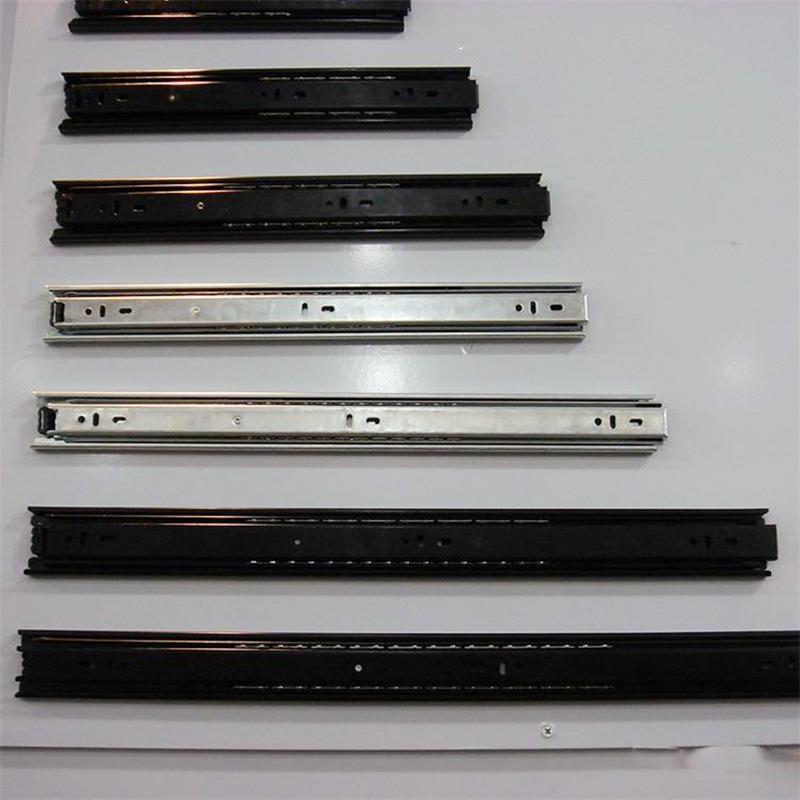

Lub rooj sib txoos ua haujlwm swb no yog tsim los ntawm peb txheej ntawm cov pob txha txias-tsim qhov "1", "2", thiab "3", nrog rau cov pob thiab tawb hauv nruab nrab.Peb txheej ntawm cov pob txha "1", "2", thiab "3" tuaj yeem tsim los ntawm Kev Hloov Kho Telescopic Channel Drawer Slide Roll Forming Tshuab ntau lawm.

MAIN TECHNICAL PARAMETERS

Khoom zoo:txias dov hlau, Galvanized hlau, stainless hlau

Yield zog ntawm raw khoom:235 Mpa

Coil sab nraud txoj kab uas hla:≤Φ1200 hli

Inner diameter ntawm coil:f508mm ua

Sawb dav:≤100mm

Sawb thickness:1.2 hli, 1.2mm, 1.5mm

Ib coil hnyav:≤ 2500 kg

MACHINE CONFIGURATION & SPECIFICATIONS

1. MANUAL UNCOILER 1SET

Lub tshuab no nyob rau hauv ib lub taub hau hom.

2. QIB 1 SET

Nws txais 7 rollers rau qib, 2 khub ntawm kev qhia cov menyuam, thiab cov menyuam pub noj yog pneumatically clamped thiab tswj los ntawm servo lub cev muaj zog.

3. 163T Punching Xovxwm 1 SET

Lub punching nrug yog adjustable nyob rau hauv lub transverse kev taw qhia ntawm lub phaj, thiab lub punching kauj ruam yuav hloov tau los ntawm cov hluav taws xob tswj system.txhua qhov ntev specification yog nruab nrog 1 txheej tuag cais.

4. QHOV CHAW UA HAUJ LWM ROLL FORM UNIT 1 SET

Thaum hloov cov khoom sib txawv, tsuas yog ib feem ntawm lub tes tsho muab faib yuav tsum tau hloov, thiab cov khoom tuaj yeem hloov tau sai.

Parameters:

No. of forming passes: 12

Qhov Loj: 10 + 12 + 8 = 30

Ncej txoj kab uas hla ntawm kev sib sau tshuab: φ50mm (raug tsim kawg)

Lub cev muaj zog: txog 7.5kW (raws li qhov kawg tsim)

Maximum linear ceev: 10 ~ 15m / min

5. SERVO TRACKING txiav 1 SET

Siv servo taug qab txiav tawm, ceev ceev thiab siab efficiency.Cutter khoom: Cr12MoV (hardness tom qab quenching yog HRC58 ~ 62)

6. ELECTRICAL CONTROL UNIT 1 SET

Tag nrho cov kab txais cov txiv neej-tshuab tswj hom sib txuas PLC thiab kov npo.Cov kev qhia tshwj xeeb, qhov ntau thiab qhov tsis zoo ntawm cov khoom tuaj yeem teeb tsa los ntawm lub vijtsam kov.

| Hom ntawm cov khoom siv hluav taws xob tseem ceeb | ||

| 1. | PLC | Mitsubishi, Nyiv |

| 2. | Servo Tsav | Yaskawa, Nyiv |

| 3. | Inverter | Delta (Taiwan, Suav teb) |

| 4. | Kov npo | Vinylon (Taiwan, Suav teb) |

7. HYDRAULIC STATIONS 1 SET

Cov khoom tseem ceeb yog: roj twj, lub cev muaj zog, hydraulic valve, solenoid valve, lim thiab hydraulic roj tank, thiab lwm yam.

PRODUCTION PROCESS

Uncoiling → Leveling Servo Pub → Punching → Cold Roll Forming → Servo Tracking Cutting → Discharge

KEV PAB CUAM

tub rau khoom slides yob txoj kev tshuab; tub rau khoom swb ua tshuab; telescopic tub rau khoom swb yob txoj kev tshuab; channel tub rau khoom swb yob txoj kev tshuab

Nrog rau cov thev naus laus zis thiab cov chaw tsim khoom, kev tswj xyuas zoo, tsim nyog tus nqi, lub tuam txhab tshwj xeeb thiab kev sib koom tes nrog kev cia siab, peb tau mob siab rau muab qhov zoo tshaj plaws tsim nyog rau peb cov neeg siv khoom rau 2019 Zoo Zoo Tuam Tshoj High Precision Telescopic Channel Drawer Slide Rail Roll Forming Tshuab nrog Kev Hloov Ceev, Peb lub hom phiaj yog ib txwm tsim kom muaj Win-win scenario nrog peb cov neeg siv khoom.Peb xav tias peb yuav yog koj qhov kev xaiv loj tshaj plaws."Reputation Pib nrog, Cov Neeg Yuav Khoom Ua Ntej.“Tsav koj qhov kev nug.

2019 Zoo ZooTuam Tshoj Cold Roll Forming Tshuab, Roll Forming Machine, Peb cov neeg ua haujlwm muaj kev paub dhau los thiab kev cob qhia nruj me ntsis, nrog kev paub tshwj xeeb, nrog lub zog thiab ib txwm hwm lawv cov neeg siv khoom raws li No. 1, thiab cog lus tias yuav ua lawv qhov zoo tshaj plaws los muab cov kev pabcuam zoo thiab tus kheej rau cov neeg siv khoom.Lub Tuam Txhab them nyiaj rau kev tswj hwm thiab txhim kho kev sib raug zoo nrog cov neeg siv khoom mus sij hawm ntev.Peb cog lus tias, raws li koj tus khub zoo tshaj plaws, peb yuav txhim kho lub neej yav tom ntej thiab txaus siab rau cov txiv hmab txiv ntoo uas txaus siab ua ke nrog koj, nrog rau kev mob siab rau, tsis muaj zog thiab lub siab xav mus tom ntej.